Automated Fabrication Systems brings together vendors who you can trust.

We help you find the best machinery & tooling to suit your specific needs!

Call now for personalized service!

Marten Weidgraaf

+1 847-867-6187

Automated Fabrication Systems, LLC

Ursviken press brakes empowers productivity for the most demanding metal bending operations.

We offer a comprehensive package of high-quality solutions and life cycle service

read more

We’ve been providing innovative solutions with a focus on quality and value for over 100 years!

read more

Ursviken is a leading manufacturer of CNC press brakes for sheet metal and plate.

read more

Enhanced productivity for a variety of industries

The group companies offer enhanced productivity to customers operating in a variety of industries, including telecommunication, electronics, machine manufacturing, construction equipment, tube and pole manufacturing as well as ship building.

Experts in metal sheet working:

Ursviken Technology is a source for knowledge and service in metal working equipment. Our extensive knowledge and experience enable us to provide the customer with solutions and services that ensures a better return on investment.

Extensive product support

All our machines include a comprehensive warranty and training program. Additionally, we offer a wide range of services including maintenance contracts, remote diagnostics (via modem or Internet), and application support. A wide range of training courses is available to suit individual customer requirements.

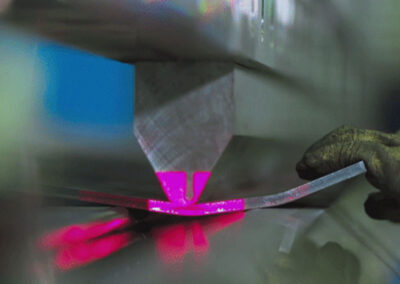

OPTIMA Press Brake

Optima meets the highest demands when it comes to plate fabrication. Accuracy, performance, efficiency, and quality is our foundation.

The Optima press brake can be customized to suit individual applications with different daylight, stroke, throat depth, bend length and a lot of options when it comes to handling equipment.

For large poles, tubes, crane arms and forming thicker plates in high strength steel, this is the product of choice.

Optima press brakes tonnage capacity starts at 440Tons up 5500Tons and single lengths up to 68’

Common options available with the Ursviken Optima CNC Press brake

- Lift/Swing (material support/follower)

- Six Axis back gauge

- Programmable lower dies

- Angle control system with automatic compensation

- Application driven tooling packages

- CNC Tool magazine and indexable tool radius

- CNC-crowning (deflection compensation)

- Tandem operation

- Material handling systems

The Ursviken Group is a global business network of metal working solutions and service support providers. Building on a solid experience and history of over a century at the forefront of metal working and sheet metal fabrication, we offer a comprehensive package of high-quality solutions and life cycle services – enabling customers in over 100 countries to take a tiger leap in productivity and increase the return of investment, ROI.

Ursviken Technology Ursviken Technology was established as a manufacturer of machine tools in 1885 – spanning three centuries! Continuous investment in research and development has resulted in design concepts that have given our products a worldwide reputation. By listening to our customers and providing innovative solutions to suit their requirements with a focus on quality and value, we believe that our continued success is assured and our position as the market leader will be retained. This is a position that we plan to keep and strengthen.

Ursviken Optima – advanced forming technology for plate fabrication Ursviken is a leading manufacturer of CNC press brakes for sheet metal and plate, that has for more than 60 years continuously improved and developed press brake bending technology. With this extensive experience, the OPTIMA series has been developed to meet the demands of plate fabrication. With ongoing research and development Ursviken is uniquely qualified to deliver machines with accuracy, performance, efficiency, and quality as their foundation The Optima press brake has features that will optimize the bending result, regardless of material thickness and quality. These features reduce set up time and eliminate trial and error bending thus increasing productivity. The Optima press brake can be customized to suit individual applications with different daylight, stroke, throat depth and bend length. The Optima can be equipped with light guards or security by laser beams, to facilitate a safe bending environment. Of equal importance is to provide the operator(s) with an ergonomic working environment. The Optima can be fitted with material handling/supports. A comprehensive training program is included with each Optima.